CLK_ADJ

Posted: 13 Mar 2020, 19:10

The turntable-speed selector switch on the control panel of THE LATHE selects which pull-up resistor's 5-V signal will be removed (by grounding it) from which NAND gate input on the TT Servo Drive board so as to select the correct speed-reference frequency modulo of its 432-kHz master clock (crystal) (...from the Fairchild 9305 (TTL, 14-pin DIL) variable modulus counters), and, by having more than one deck of 'poles', the switch simultaneously makes additional selections, including which resistor to signal 5 V to on the Variable Pitch board so that the RC network on it will cause its 555 oscillator circuit to make the correct frequency of its pulse-train output for the sampling of automation audio peaks to happen 25 times per turntable revolution at the selected angular velocity.

{The four-deck switch also selects which electro-magnetic relay to energize on the Feed Servo board in order to select the correct turntable-speed compensation network for banding and expansion, and base pitch.}

The basic circuit is illustrated at an online 555 frequency calculator, using the part as an astable multivibrator . The Variable Pitch board's 555 frequency is established by having a 620-Ohm resistor as R2 (shared by all speed settings), and a selectable fixed resistor (changing resistance for each change of tt speed), plus a 5-kiloohm trimpot (combined), as R1. The capacitor, which is also shared for all speed settings, is specified as 4.7 µF. The fixed resistor used in R1 is selectable via the turntable-speed switch, but the same trimpot is used by the selectable fixed resistors for all three turntable-speed settings.

(The updated TT Servo Drive board's tt speed can be, either, '33', '45'. or, for CD-4 cutting, 'half-speed', which can be either half-speed '33' (i.e., 16+2/3 RPM), or half-speed '45' (i.e., 22+1/2 RPM.), but the Variable Pitch board's fixed resistor for 1/2-speed-(RPM)-compensation of logical expansions is for 16+2/3 RPM and would have to be lowered in resistance to work best with 22+1/2 RPM. (The original LS-76 'OSC' board was designed to drive a larger platter which is 17+1/4" in diameter, suitable for hosting a 16" transcription disk's oversized lacquer master, which is no longer made by any lacquer master manufacturer.))

R60 is a 16.9-kΩ resistor for the '33 FEED CLOCK' frequency network. The peak voltages of the audio sent to the disk computer (Variable Pitch and Variable Depth boards), which is RC-network-bass-emphasized on input to the Variable Pitch board µA748 op amps, A10 and A1 (for the L/L component), and L-R-summed, out-of-phase (by a United Transformer Company model A18 audio transformer within the card cage), just prior to RC-network-bass-emphasis on input to the Variable Depth board µA748 op amp, A2 (for the L/V component), and which are 'stored' (as in, measured, and passed on) at the rate of 25 peak values per turntable revolution, are acted upon up to 5 times per revolution, but only if an expansion beyond the base pitch would be needed so as to avoid over-cutting. (Depth increases are also triggered by the out-of-phase copy of the automation audio.) The advance copies of the program audio that go to the lathe's pitch and depth automation circuits precede the cutting signal by a full turntable revolution. A copy of the left channel program signal (for the pitch automation) also goes to the lathe at the same time as the original goes to the left channel cutting amp, but it isn't acted upon by the disk computer until the following turntable revolution.

{Using a copy of the left channel advance signal won't work for the pitch control with this circuit, since it can only 'store' the data for a single turntable revolution, but it isn't acted upon until the revolution subsequent to that during which the left channel groove-modulation occurs, whereas the calculated depth changes are acted upon as the respective signals are being cut, just as with the right channel pitch automation, so those signals need to be well enough in advance for the circuits to measure the audio peaks and calculate the necessary adjustments to the base pitch and depth. Disk computers made only four years later (e.g., Sontec Compudisk) were able to 'store' the audio peak data for longer intervals and, therefore, only needed a left and a right copy of the program signal to be sent in advance of the cutting signals.}

If the automation audio has an actionable peak voltage that persists, remaining at the exact same level throughout all five sectors of the platter at which an expansion might be made, or even for multiple, consecutive, turntable revolutions, such as when cutting a sustained, low-frequency organ note, or when cutting any continuous low frequency (e.g., 200 Hz), especially when out of phase, or merely a loud enough midrange signal (i.e., 1 kHz at 7 cm/sec peak lateral velocity) sine wave (during calibration or, possibly, the mastering of a test record), the required expansions will happen only once per revolution, as a 'pulse' of acceleration, not unlike hitting 'Return' on a manual typewriter. As THE LATHE's disk computer is cognizant of the automation audio's absolute polarity, the modulation of adjacent groove turns results in visible 'spooning' of positionially-compatible excursions of the same frequency under the microscope. By including the combination of the temporal 'location' and polarity of the maximal excursions from the previous and subsequent revolutions, the expansions above base pitch are greater where neighboring peaks in groove modulation face each other, and lesser where neighboring peaks in groove modulation 'chase' each other, so as to maintain the same amount of unclaimed land between peaks in groove modulation. A peak of groove modulation cut next to a turn of silence (or otherwise unexpanded pitch) may occasionally cause touching at the tops of the outer and inner walls, respectively, of adjacent turns of the groove, though without overcutting. While such brief and minimal edge contact of the tops of adjacent turns of the groove wall is permissible, and seen in densely-packed cuts by professional cutting engineers using the Sontec Compudisk and Zuma disk computers because it maximizes the economical use of the available 'land' on a side, in order to avoid any groove-wall edge-contact, an offset to the automation audio can be applied to either the pitch or depth control circuits' respective offset attenuators, or to both at once, and/or, if one is familiar with the program, a manual override to the pitch and/or depth automation can be performed during the cut at times where more expansion than normal is wanted by the flip of a switch called, Expand, and the adjustment of the Depth dial.

For 25 samples to be evenly spaced during a full turntable revolution at 33+1/3 RPM, the reference frequency, corresponding to the frequence of (unipolar) sampling, needs to be 13.888...Hz. This is because one revolution at 33+1/3 RPM takes 1.8 seconds.

[25 / 1.8 = 13.888... / 1.0]

For 45 RPM, the reference frequency needs to be 18.75 Hz, since the turntable revolution at 45 RPM only takes 1.333... seconds.

[25 / 1.333... = 18.75 / 1.0]

On #656, I checked the 'CLK' test point (F) on the Variable Pitch board using a frequency counter. It indicated that the reference frequency at '33' was over 14 Hz. The '45' feed clock signal, however, was already at 18.75 Hz, so, I couldn't tweak the 'CLK ADJ' trimpot in order to fine-tune the '33' feed clock signal from 14+ Hz down to 13.888 Hz without inadvertently changing the feed clock frequency for 45 RPM.

{I read that a 555 astable multivibrator circuit may deliver results that deviate from the calculated values of the arranged components by as much as 20%, which would mean the '33' feed clock might have been making anything from 11.573 Hz through 16.66 Hz and be within the tolerance of the generic circuit. L. J. Scully cherry-picked very accurate resistor values for the fixed resistors (within 0.059% of target), but the ideal performance of the circuit can only be realized by testing how the actual chip used behaves with the theroretically-correct network and then modifying that, if necessary, or when parts get changed over the years, out in the field, such as when a capacitor, or the 555 IC chip, itself, is replaced, the empirical results would be, again, unpredictable. So, this procedure corrects for such offsets from the design targets.}

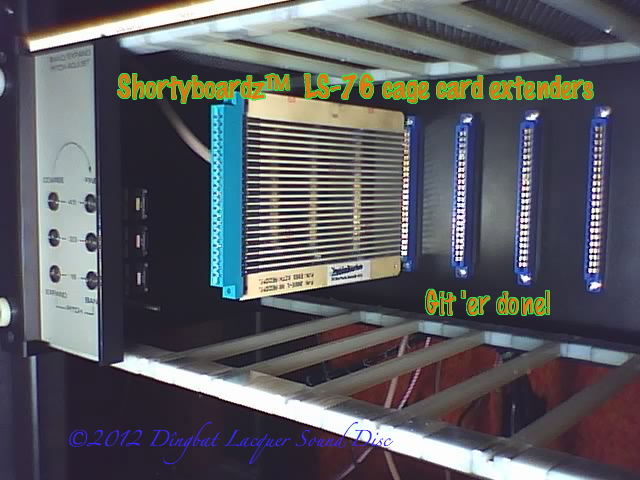

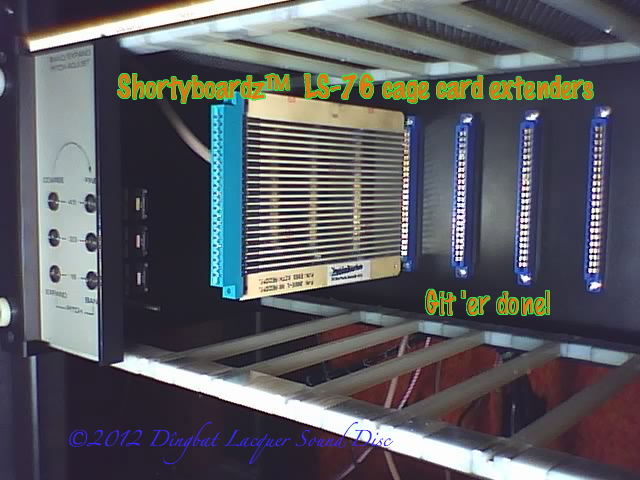

Adjusting the feed clock requires extending the Variable Pitch board with two mated (22-pin) Shortyboardz™ so that it's pushed out of the cage far enough for one to reach the 'CLK ADJ' trimpot and test point, F, at the back of the board. Means of supporting the fully-extended board must be improvised, but the partially-extended board, when using just one Shortyboardz™ extender, remains vertically stable by having part of its own upper and lower edges remain in the cage slots. (See image, below, of one such extender board (originally made to extend the PCB inside a channel of an Ampex ATR-100 tape machine's input/output assembly (a.k.a., 'penthouse VU meters').))

So, in order to avoid having to adjust the clock every time I switch turntable speeds, I had to add a fixed resistor to the '33 CLK''s R1 network. Rather than putting a soldering iron on the circuit board unnecessarily, I decided to add the helping resistor to the turntable-speed selector switch contact for wire 202-C that goes to V.P. edge connector pin D and on to the 16.9-kΩ fixed resistor and 5-kΩ trimpot. (The rear of the control panel where the contacts of the turntable-speed selector switch are found can be accessed by lifting the 24" x 7" x 3/8" panel out of its frame. Two double-snakes are tied to the rear of the panel which fan out as multiple wires going to the switches, meters, and pushbuttons, as well as the LPI Display board. The double-snakes' other ends go inside the steel weldment and to two Winchester gold-plated-pin chassis connectors on the rear of the card cage, below. There's just enough slack on the snakes to allow the control panel to be flipped over and repositioned in the same frame in front of the A-table.)

First, after powering down the lathe, I unsoldered wire 202-C from the back of the switch and clipped to it one of the leads of a Shallcross decade resistance box.

The box's other lead was clipped to the contact on the turntable-speed selector switch for '33 FEED CLOCK'. I then powered back on THE LATHE and read the frequency counter display as I adjusted the decade resistance box switches until I saw 13.888... Hz.

The target resistance appeared to be 863 Ohms. To my surprise, I found a resistor in the studio shop that measured 836 Ohms. So, I thought I'd try it. It actually worked perfectly, causing the frequency counter to display 0.013888 kHz at the '33' turntable-speed switch step (when trimpot R62 was deflected identically to its value of resistance that causes the frequency counter to display 0.01875... kHz at the '45' turntable-speed switch step). I was willing to add a 27-Ohm resistor to 202-C's helping resistor, but it wasn't necessary. I was a little more surprised to notice later that morning, before I drove away from the 2836 address, that my car's trip odometer (an orange dot matrix display) read 836 mi. (!)

I performed the identical procedure on lathe #660. It required 430.1 Ohms for the '33 FEED CLOCK' switch contact. I used a 300.1-Ohm resistor which I found, first, added to a cherry-picked (from 20 different 1%-tolerance, '130-Ohm' metal film resistors) 130.0-Ohm resistor for that. Two of their four (combined) legs were twisted together in a Western-Union splice and soldered and covered with heat-shrink tubing, shrunk with a heat gun after soldering in place their other two (combined) legs - one, to the '33 FEED CLOCK' switch contact and, the other, to wire 202-C.

I looked at the 13.888 Hz signal from the 555 test point for both lathes on an oscilloscope (with a probe compensated for square wave reading on that scope) and saw no overshoot or noise, The duty cycle is as the calculator indicated, about 97% 'on'...

{The four-deck switch also selects which electro-magnetic relay to energize on the Feed Servo board in order to select the correct turntable-speed compensation network for banding and expansion, and base pitch.}

The basic circuit is illustrated at an online 555 frequency calculator, using the part as an astable multivibrator . The Variable Pitch board's 555 frequency is established by having a 620-Ohm resistor as R2 (shared by all speed settings), and a selectable fixed resistor (changing resistance for each change of tt speed), plus a 5-kiloohm trimpot (combined), as R1. The capacitor, which is also shared for all speed settings, is specified as 4.7 µF. The fixed resistor used in R1 is selectable via the turntable-speed switch, but the same trimpot is used by the selectable fixed resistors for all three turntable-speed settings.

(The updated TT Servo Drive board's tt speed can be, either, '33', '45'. or, for CD-4 cutting, 'half-speed', which can be either half-speed '33' (i.e., 16+2/3 RPM), or half-speed '45' (i.e., 22+1/2 RPM.), but the Variable Pitch board's fixed resistor for 1/2-speed-(RPM)-compensation of logical expansions is for 16+2/3 RPM and would have to be lowered in resistance to work best with 22+1/2 RPM. (The original LS-76 'OSC' board was designed to drive a larger platter which is 17+1/4" in diameter, suitable for hosting a 16" transcription disk's oversized lacquer master, which is no longer made by any lacquer master manufacturer.))

R60 is a 16.9-kΩ resistor for the '33 FEED CLOCK' frequency network. The peak voltages of the audio sent to the disk computer (Variable Pitch and Variable Depth boards), which is RC-network-bass-emphasized on input to the Variable Pitch board µA748 op amps, A10 and A1 (for the L/L component), and L-R-summed, out-of-phase (by a United Transformer Company model A18 audio transformer within the card cage), just prior to RC-network-bass-emphasis on input to the Variable Depth board µA748 op amp, A2 (for the L/V component), and which are 'stored' (as in, measured, and passed on) at the rate of 25 peak values per turntable revolution, are acted upon up to 5 times per revolution, but only if an expansion beyond the base pitch would be needed so as to avoid over-cutting. (Depth increases are also triggered by the out-of-phase copy of the automation audio.) The advance copies of the program audio that go to the lathe's pitch and depth automation circuits precede the cutting signal by a full turntable revolution. A copy of the left channel program signal (for the pitch automation) also goes to the lathe at the same time as the original goes to the left channel cutting amp, but it isn't acted upon by the disk computer until the following turntable revolution.

{Using a copy of the left channel advance signal won't work for the pitch control with this circuit, since it can only 'store' the data for a single turntable revolution, but it isn't acted upon until the revolution subsequent to that during which the left channel groove-modulation occurs, whereas the calculated depth changes are acted upon as the respective signals are being cut, just as with the right channel pitch automation, so those signals need to be well enough in advance for the circuits to measure the audio peaks and calculate the necessary adjustments to the base pitch and depth. Disk computers made only four years later (e.g., Sontec Compudisk) were able to 'store' the audio peak data for longer intervals and, therefore, only needed a left and a right copy of the program signal to be sent in advance of the cutting signals.}

If the automation audio has an actionable peak voltage that persists, remaining at the exact same level throughout all five sectors of the platter at which an expansion might be made, or even for multiple, consecutive, turntable revolutions, such as when cutting a sustained, low-frequency organ note, or when cutting any continuous low frequency (e.g., 200 Hz), especially when out of phase, or merely a loud enough midrange signal (i.e., 1 kHz at 7 cm/sec peak lateral velocity) sine wave (during calibration or, possibly, the mastering of a test record), the required expansions will happen only once per revolution, as a 'pulse' of acceleration, not unlike hitting 'Return' on a manual typewriter. As THE LATHE's disk computer is cognizant of the automation audio's absolute polarity, the modulation of adjacent groove turns results in visible 'spooning' of positionially-compatible excursions of the same frequency under the microscope. By including the combination of the temporal 'location' and polarity of the maximal excursions from the previous and subsequent revolutions, the expansions above base pitch are greater where neighboring peaks in groove modulation face each other, and lesser where neighboring peaks in groove modulation 'chase' each other, so as to maintain the same amount of unclaimed land between peaks in groove modulation. A peak of groove modulation cut next to a turn of silence (or otherwise unexpanded pitch) may occasionally cause touching at the tops of the outer and inner walls, respectively, of adjacent turns of the groove, though without overcutting. While such brief and minimal edge contact of the tops of adjacent turns of the groove wall is permissible, and seen in densely-packed cuts by professional cutting engineers using the Sontec Compudisk and Zuma disk computers because it maximizes the economical use of the available 'land' on a side, in order to avoid any groove-wall edge-contact, an offset to the automation audio can be applied to either the pitch or depth control circuits' respective offset attenuators, or to both at once, and/or, if one is familiar with the program, a manual override to the pitch and/or depth automation can be performed during the cut at times where more expansion than normal is wanted by the flip of a switch called, Expand, and the adjustment of the Depth dial.

For 25 samples to be evenly spaced during a full turntable revolution at 33+1/3 RPM, the reference frequency, corresponding to the frequence of (unipolar) sampling, needs to be 13.888...Hz. This is because one revolution at 33+1/3 RPM takes 1.8 seconds.

[25 / 1.8 = 13.888... / 1.0]

For 45 RPM, the reference frequency needs to be 18.75 Hz, since the turntable revolution at 45 RPM only takes 1.333... seconds.

[25 / 1.333... = 18.75 / 1.0]

On #656, I checked the 'CLK' test point (F) on the Variable Pitch board using a frequency counter. It indicated that the reference frequency at '33' was over 14 Hz. The '45' feed clock signal, however, was already at 18.75 Hz, so, I couldn't tweak the 'CLK ADJ' trimpot in order to fine-tune the '33' feed clock signal from 14+ Hz down to 13.888 Hz without inadvertently changing the feed clock frequency for 45 RPM.

{I read that a 555 astable multivibrator circuit may deliver results that deviate from the calculated values of the arranged components by as much as 20%, which would mean the '33' feed clock might have been making anything from 11.573 Hz through 16.66 Hz and be within the tolerance of the generic circuit. L. J. Scully cherry-picked very accurate resistor values for the fixed resistors (within 0.059% of target), but the ideal performance of the circuit can only be realized by testing how the actual chip used behaves with the theroretically-correct network and then modifying that, if necessary, or when parts get changed over the years, out in the field, such as when a capacitor, or the 555 IC chip, itself, is replaced, the empirical results would be, again, unpredictable. So, this procedure corrects for such offsets from the design targets.}

Adjusting the feed clock requires extending the Variable Pitch board with two mated (22-pin) Shortyboardz™ so that it's pushed out of the cage far enough for one to reach the 'CLK ADJ' trimpot and test point, F, at the back of the board. Means of supporting the fully-extended board must be improvised, but the partially-extended board, when using just one Shortyboardz™ extender, remains vertically stable by having part of its own upper and lower edges remain in the cage slots. (See image, below, of one such extender board (originally made to extend the PCB inside a channel of an Ampex ATR-100 tape machine's input/output assembly (a.k.a., 'penthouse VU meters').))

So, in order to avoid having to adjust the clock every time I switch turntable speeds, I had to add a fixed resistor to the '33 CLK''s R1 network. Rather than putting a soldering iron on the circuit board unnecessarily, I decided to add the helping resistor to the turntable-speed selector switch contact for wire 202-C that goes to V.P. edge connector pin D and on to the 16.9-kΩ fixed resistor and 5-kΩ trimpot. (The rear of the control panel where the contacts of the turntable-speed selector switch are found can be accessed by lifting the 24" x 7" x 3/8" panel out of its frame. Two double-snakes are tied to the rear of the panel which fan out as multiple wires going to the switches, meters, and pushbuttons, as well as the LPI Display board. The double-snakes' other ends go inside the steel weldment and to two Winchester gold-plated-pin chassis connectors on the rear of the card cage, below. There's just enough slack on the snakes to allow the control panel to be flipped over and repositioned in the same frame in front of the A-table.)

First, after powering down the lathe, I unsoldered wire 202-C from the back of the switch and clipped to it one of the leads of a Shallcross decade resistance box.

The box's other lead was clipped to the contact on the turntable-speed selector switch for '33 FEED CLOCK'. I then powered back on THE LATHE and read the frequency counter display as I adjusted the decade resistance box switches until I saw 13.888... Hz.

The target resistance appeared to be 863 Ohms. To my surprise, I found a resistor in the studio shop that measured 836 Ohms. So, I thought I'd try it. It actually worked perfectly, causing the frequency counter to display 0.013888 kHz at the '33' turntable-speed switch step (when trimpot R62 was deflected identically to its value of resistance that causes the frequency counter to display 0.01875... kHz at the '45' turntable-speed switch step). I was willing to add a 27-Ohm resistor to 202-C's helping resistor, but it wasn't necessary. I was a little more surprised to notice later that morning, before I drove away from the 2836 address, that my car's trip odometer (an orange dot matrix display) read 836 mi. (!)

I performed the identical procedure on lathe #660. It required 430.1 Ohms for the '33 FEED CLOCK' switch contact. I used a 300.1-Ohm resistor which I found, first, added to a cherry-picked (from 20 different 1%-tolerance, '130-Ohm' metal film resistors) 130.0-Ohm resistor for that. Two of their four (combined) legs were twisted together in a Western-Union splice and soldered and covered with heat-shrink tubing, shrunk with a heat gun after soldering in place their other two (combined) legs - one, to the '33 FEED CLOCK' switch contact and, the other, to wire 202-C.

I looked at the 13.888 Hz signal from the 555 test point for both lathes on an oscilloscope (with a probe compensated for square wave reading on that scope) and saw no overshoot or noise, The duty cycle is as the calculator indicated, about 97% 'on'...